This article is part of Orbia’s Megatrendsetters blog series, which explores how Orbia’s solutions are driving the transformative forces, or “megatrends” that are advancing our society, from decarbonization and the circular economy to shifting supply chains and agribusiness to global water and digitalization. To learn more about the Tegra 600, visit the Orbia Building & Infrastructure website here.

The new Tegra 600 LC product has a longer lifetime, is easier to install and is more sustainable than the prior generation

The new Tegra 600 LC product has a longer lifetime, is easier to install and is more sustainable than the prior generation

As cities face the growing challenges of climate change—more frequent flooding, aging infrastructure and rising sustainability demands—the need for resilient, future-ready urban systems has never been greater. Orbia’s Building & Infrastructure business group (Wavin) creates infrastructure to be the foundation of healthier, more sustainable communities above ground.

A key component to this approach is the Tegra 600 inspection chamber, a solution that has supported wastewater and rainwater management for more than two decades.

In this Q&A, we spoke with Mark Vlok, Global Product Manager for Manholes and Inspection Chambers at Orbia Building & Infrastructure (Wavin), about how the Tegra 600 has evolved to be more sustainable, the challenges and breakthroughs behind its redesign and what comes next as Orbia Building & Infrastructure continues to shape the future of urban climate resilient infrastructure.

Mark Vlok, Global Product Manager for Manholes and Inspection Chambers at Orbia Building & Infrastructure (Wavin)

Mark Vlok, Global Product Manager for Manholes and Inspection Chambers at Orbia Building & Infrastructure (Wavin)

Q: Can you provide an overview of the Tegra product and how it has evolved over time?

A: Tegra has been part of the Orbia Building & Infrastructure product portfolio for more than 20 years. It helps inspect below ground pipe systems for wastewater and rainwater, which is an essential function for keeping cities safe from flooding, protecting public health and ensuring the reliability of critical infrastructure.

In September 2025, we launched the next generation of this product: the Tegra 600 LC (Low Carbon). This redesign reflects our commitment to not only meet customer needs today, but also to anticipate future global standards and lead the way in sustainable design.

The Tegra 600 LC is built to last up to 100 years, made with up to 70% recycled material and produced with 50% less energy, cutting its carbon footprint by 45–70% depending on the configuration.

Two sustainability features make the product a leader in the market: it is 100% recyclable at end of life, and it is manufactured in facilities powered by 100% renewable energy.

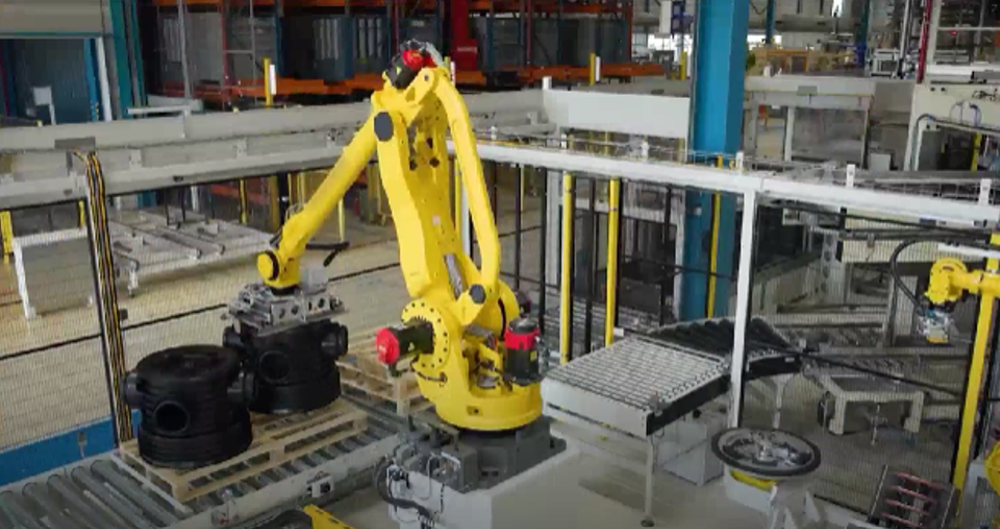

The Tegra product undergoes rigorous testing for leak tightness and durability before being shipped to customers

The Tegra product undergoes rigorous testing for leak tightness and durability before being shipped to customers

Q: What were the key challenges in redesigning the Tegra 600, and how did Orbia B&I address them?

A: Transitioning from virgin materials to recycled materials was a substantial challenge. Success required early involvement from colleagues across functions—from R&D and procurement to technical experts and customers themselves. Setting clear sustainability targets early in the design process made it possible for everyone to align on what we wanted to achieve.

Another factor was the evolution of industry standards in Europe. During development, new requirements for inspection chambers, including the EN13958-2 standard, allowed for greater sustainability. This shift provided both external validation and extra motivation to innovate.

We also had to build new partnerships with recyclers and compounders to secure the right materials. Because recycled materials were new for this type of application, extensive testing was required—each cycle taking about nine months. It took several iterations to identify the right solutions together with our suppliers. Now, the knowledge and test results we’ve gained not only support Tegra but will also inform future sustainable product designs.

If I had to sum up the key lesson, it’s this: start early, set clear sustainability goals and work in close cooperation across the value chain.

Q: How have customers responded to the redesigned Tegra 600 LC?

A: Customers have been closely involved in this journey from the very beginning. In fact, we started conversations with them three to four years ago to understand both the benefits they were seeking and the concerns they might have.

One concern that came up often was product lifespan. Customers wanted to be sure that a more sustainable product would not mean sacrificing durability. That feedback pushed us to raise the bar significantly. The Tegra 600 LC is designed and tested to last 100 years or longer—more than double the lifespan of the previous version.

Our redesign also made the product lighter and easier to install, with no need for heavy machinery. We also have new ball joint adapters on the product that offer 30% more flexibility than the previous generation, allowing installers to navigate unforeseen obstacles with ease.

As a result, customer response has been very positive and we’re seeing customers start to change their tendering process to incorporate priority for sustainable design features.

The Tegra product from Orbia Wavin is available in European markets with further global availability for projects and partners anticipated in the near future.

The Tegra product from Orbia Wavin is available in European markets with further global availability for projects and partners anticipated in the near future.

Q: What are the next steps in the development and deployment of the Tegra 600 LC?

A: Looking ahead, we’re focused on three priorities for the Tegra 600.

First, we’ll continue to strengthen partnerships with recyclers and compounders to secure high-quality recycled materials. This will give us greater control over inputs, more agility in innovation and the ability to fine-tune material recipes with confidence.

Second, we’re applying the same sustainability-first mindset to redesign other products in our below-ground portfolio, including inspection chambers and manholes.

Finally, we’re working closely with customers and industry partners to highlight the proven benefits of this next-generation solution, ensuring that sustainability is recognized and rewarded in tendering processes.

Sustainable design will only become more critical with tightening global regulations and increased strain put on our water infrastructure from growing populations. We see a strong future and competitive advantage for the Tegra line and look forward to expanding our sustainable product portfolio.