Decarbonization & Energy Transition

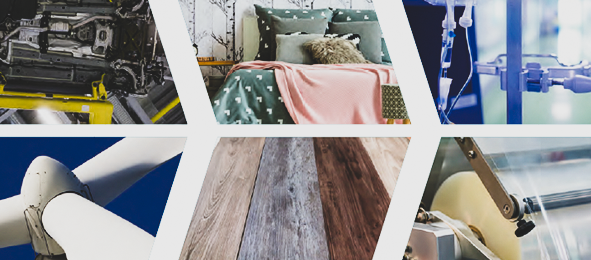

Cities worldwide are under stress with population growth, aging infrastructure, flooding, droughts, pollution and sinking land. Orbia provides resilient and sustainable urban infrastructure solutions to address systemic risks, along with low-carbon and circular products that contribute to resiliency and decarbonization globally.

In addition to our solutions, Orbia is a partner of the Resilient Cities Network. Through our businesses Wavin, Netafim and Dura-Line, we are developing innovative solutions for transportation infrastructure, water supply, urban food systems, and connectivity that can enhance urban quality of life.

Our contributions to the SDGs:

Direct

|

|

|

|

Indirect

|

|

|

|

|

|

|

|

How Orbia is making a difference:

Alternative Energy

Powering the Next Generation of U.S. Battery Innovations

Take a look inside Orbia’s breakthrough custom electrolyte business—essential to powering batteries used in new technology such as long-range drones and AI data centers. Since launching, the business has supported 100+ customers, increased output 3X over and is on track to have a production capacity of 400 tons/year by the end of 2025. Read the article to learn more about how Orbia is accelerating battery innovation and building a secure domestic supply chain for the U.S.

Advancing low-carbon mobility

Orbia announced a joint venture with Solvay to build the largest polyvinylidene flouride (PVDF) facility in North America.

Orbia’s Fluor & Energy Materials business group and Polymer Solutions business Vestolit will supply key materials and expertise to close a significant supply gap while promoting regional production and security of a material that optimizes battery energy storage efficiency. Additionally, a $100 million grant was awarded from the U.S. Department of Energy (DOE) to build the first U.S. manufacturing plant for lithium hexafluorophosphate (LiPF6) on the grounds of F&EM’s existing production site in St. Gabriel, Louisiana. This plant will produce enough LiPF6 to support domestic production of more than one million full-electric vehicles annually.

Resource Efficiency

How Orbia is Creating Cost Effective Graphite Recycling from EV Batteries

Orbia’s Fluor & Energy Materials business has developed a breakthrough process to recover, purify and upcycle graphite from domestic sources. The proprietary technology creates ultra high purity upcycled graphite indistinguishable from pristine graphite. It is economically viable and produces up to 4x less CO₂ than synthetic graphite and up to 2x less CO₂ than mined natural graphite.

Vinyl in Motion

Our PVC recycling program, Vinyl in Motion, continues to evolve and expand. The program converts over 530,000 kg of vinyl waste per year into high-quality raw materials and empowers recyclers with grants and support to become entrepreneurs. In 2024 the Vinyl in Motion program achieved several key milestones, successfully launching a vinyl artificial leather stream at a production rate of 10 tons per month, expanding the construction stream to meet increased demand from Orbia Building & Infrastructure at 60 tons per month and growing adoption from home dialysis patients and medical centers at an annual rate of 15%. Overall, the program grew 83% in 2024 compared to 2023 and Orbia expects to double its recycled PVC production capacity in 2025.

Low-Carbon Water Solutions for Urban Climate Resilience

Orbia’s Building & Infrastructure business (Wavin) boosts urban climate resilience with advanced water management solutions for flood prevention. Wavin’s low-carbon, easy-to-install systems, like AquaCell 400 and Q-Bic Plus, manage extreme rainfall. In 2024, Wavin launched a 100% circular polypropylene version of Q-Bic Plus, cutting CO2 emissions by 80%. The product’s environmental impact was validated with the Q-Bic Plus LC Environmental Product Declaration (EPD) for its reduced environmental impact.

ECO compounds

Orbia Polymer Solutions (Alphagary) has developed a process to recover Dioctyl Phthalate (DOP) plasticizer from blender cleaning water, producing plasticizer with 30-40% recycled DOP. This solution, effective in footwear compounds, has already produced 60 metric tons of material. In 2024, Orbia repurposed over 10 million PET bottles into DOTP plasticizers, supporting the circular economy. The recycled DOTP (rDOTP) has been certified for medical use, with 15 metric tons of rDOTP integrated into 370 metric tons of high-performance compounds.

Water management with recycled and bio-based materials

Building & Infrastructure's current portfolio already offers rainwater harvesting units and road gullies made from 100% recycled materials, and Recycore PVC pipes are produced with at least 40% recycled plastics, with zero compromise on performance. After introducing bio-circular PVC in 2022, the bio-circular portfolio has been expanded to bio-circular PE-RT for underfloor heating and bio-circular PE for drinking water pipe systems.

Full-scale circularity program

Netafim launched a full-scale circularity program in Mexico to tackle plastic waste in agriculture. By opening Mexico’s largest agricultural plastics recycling facility in Culiacan, which will be able to initially process of over 3,000 tons of plastic per year. This facility is now certified by SCS Global Services as the only precision irrigation company with a certified plastics recycling facility and certified recycled content in the country. This has allowed the launch of the Netafim ReGen™ AgVantage Certification Program, creating a new standard for Orbia Netafim's grower partners.

Bio-based TPE compounds

The new EVOPRENE® ECO 1000 series is formulated with 25% bio-based raw materials, reducing reliance on traditional fossil-based raw materials. Comparing it against a compound formulated with traditional fossil-based raw materials, Alphagary found consistent mechanical properties, good heat resistance, and consistent flow characteristics and surface finish compared with traditionally formulated compounds.

Circularity-enabling stabilizers

VINASTAB® stabilizers bring PVC to life for a variety of applications, including healthcare masks and tubing, irrigation systems, electric vehicle charging systems, rainwater harvesting and flood protection products, as well as purpose-designed formulations that support the use of recycled PVC. This series was designed in collaboration with Wavin, to help bring more stability and consistency to the extrusion process of Wavin’s Recycore products that use recycled PVC.

Circularity in Connectivity Solutions

MicroDucts are typically made from virgin High-Density Polyethylene (HDPE) but there is naturally some fallout from the manufacturing process. Orbia's Connectivity Solutions Business Dura-Line has introduced ECO products composed of up to 100% reground internal scrap. These offerings are being verified by a third-party to comply with customers’ expectations.

Low-Carbon Solutions

Low Carbon Product Design

Orbia’s Building & Infrastructure business group (Wavin) creates infrastructure to be the foundation of healthier, more sustainable communities above ground. A key component to this approach is the Tegra 600 inspection chamber, a solution that has supported wastewater and rainwater management for more than two decades. This Q&A with Mark Vlok explores the sustainable redesign of the Tegra 600 LC inspection chamber. The new generation of the Tegra product is designed and tested to last 100 years, made with up to 70% recycled material and produced with 50% less energy. Dive into the story behind this breakthrough in climate-resilient infrastructure.

Climate-friendly refrigerants

Orbia Fluor & Energy Materials is at the forefront of low-carbon refrigerant solutions. Klea® 473A won the Acrex India Award for Innovation, while Klea® 456A received the U.K. Chemicals Northwest Sustainability Award for cutting emissions by 50% in older car air conditioning systems and was shortlisted for the 2024 Chemical Industries Association Award. Orbia F&EM also offers the new R-454B refrigerant for HVAC systems, reducing GWP by 78% compared to R-410A. Orbia’s Klea® Edge™ products further strengthen its low-GWP solutions, meeting global regulations and advancing toward a net-zero future.

Greening propellants

Thirty years ago, Orbia’s Fluor & Energy Materials business introduced the most widely used propellant in inhalers: Zephex 134a. Today, it is used in two thirds of all inhalers, enabling 100 million patients to access their lifesaving medicine each year. Even as Zephex 134a became the global standard, the team launched R&D to develop a more climate-friendly solution. After 10 years of development, Zephex 152a was created, which has a 90% less global warming potential than Zephex 134a. To meet demand, Orbia F&EM is building a commercial-scale processing plant at Rocksavage, UK. The facility will boost production, reduce Scope 3 emissions by 30% and create local jobs.

Future-fit PVC

To create a future that’s fit for the next generation, we need a future-fit next generation of PVC. In 2021, Vestolit marked a milestone with the incorporation of bio-based (by balance mass approach) ethylene in vinyl chloride production. The feedstocks’ origin is rapeseed oil and used cooking oil. Both feedstocks integrate principles of circularity and do not compete with food production. This form of ethylene enables a 60-90% reduction in the carbon footprint of PVC compared to conventional fossil-fuel-based PVC.

Caustic Soda Blue

Vestolit’s PVC production plant in Marl, Germany, produces chlorine through an energy-intensive process of electrolysis. A byproduct of the electrolysis process is caustic soda, a highly versatile substance commonly used in water treatment, to raise the pH of water by absorbing water and carbon dioxide, resulting in clean water. Vestolit is sourcing renewable electricity to support the production of low-carbon caustic soda.

Energy Efficiency

Indoor climate solutions for low-carbon living

Sentio Indoor Climate Control system delivers heating and cooling via underfloor pipes, avoiding the need for air conditioning or other heating installations. Residents can control apartment temperatures using an app, saving up to 21% of energy by using zone control, up to 20% by using underfloor heating instead of radiators and up to 34% in cooling versus air conditioning.

Energy-efficient heating alternative

Calefa units provide central heating and hot water to single and multifamily homes while reducing building CO2 emissions. Wavin’s Calefa units are designed to operate at lower temperatures, considering elements like outside weather compensation and standby heat loss, also, they produce instant hot tap water.